Overview

As an important electronic component of a vehicle, car headlights need to undergo multiple electrical performance verifications during the R&D and testing phases, including load dump tests and electrostatic discharge (ESD) tests. The following is a detailed introduction to these two tests.

1.Load Dump Test

a.What is Load Dump?

Load dump refers to the situation where, when a car is running, if the battery is suddenly disconnected (e.g., the terminal is loose), the vehicle generator suddenly supplies power to the system without being absorbed by the battery, which may instantly generate a voltage shock of up to tens of volts, which may damage electronic equipment.

b.Purpose of the Test

To verify the ability of the automobile headlight circuit to withstand the generator load dump surge voltage.

c.Test Standards and Parameters

- Pulse type: Pulse 5 (5a/5b) as defined in ISO 7637-2

- Voltage amplitude: Pulse 5a-up to 87V (for 12V system) Pulse 5b-lower voltage, used to simulate battery reconnection

- Pulse duration: about 400ms

- Rise time: 5ms to 10ms

- Power supply voltage: 12V system or 24V system

- Number of repetitions: as required by OEM, usually 5~10 times

2.Electrostatic Discharge (ESD) Test

a.Purpose of the Test

Evaluate the headlight electronic system's ability to resist electrostatic discharge (ESD) interference and prevent damage caused by static electricity during assembly or use.

b.Test Standards

- ISO 10605 (Automotive complete vehicle/component ESD test standard)

- IEC 61000-4-2 (widely used in electronic equipment)

c.Test Method

- Contact discharge: for conductive surfaces

- Air discharge: for insulating material surfaces

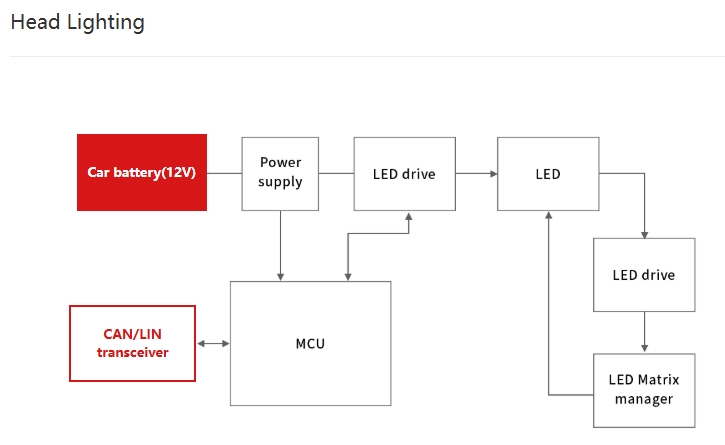

3.Protection Circuit Diagram

4.Interface and Protection Solutions

a.12V Power Port

The load dump protection circuit of the 12V power port is mainly used to deal with the high voltage pulse (Load Dump) generated by the battery disconnection in the automotive power system. Its instantaneous voltage may reach 60V~100V, causing fatal damage to the back-end electronic equipment.

It is recommended to use TPSMCJ33CA automotive TVS diode, which meets the AEC-Q101 certification standard:

b.CAN Bus Interface

CAN bus is a widely used communication bus in automobiles and industrial systems. Electrostatic discharge (ESD) protection is critical because its physical layer is often exposed to the outside of the vehicle or the connector interface and is susceptible to static interference. Goals of CAN bus ESD protection:

- Resist electrostatic discharge (ESD) voltage (±8kV~±25kV)

- Resist surge and electrical fast transients (such as ISO 7637, ISO 10605)

- Do not affect CAN signal quality (do not add too much capacitance)

- Meet automotive standards (such as AEC-Q101, ISO 11898)

It is recommended to use TPSE23T20B24LB automotive ESD suppressor, which meets the AEC-Q101 certification standard. It has the characteristics of small leakage current, fast response speed (nS level), high reliability, etc., and is widely used in ESD protection of high-speed signal transmission interfaces such as HDMI, USB, VGA, etc. in automotive electronic equipment:

c.LIN Bus Interface

LIN bus (Local Interconnect Network) is commonly used in automobiles for low-speed, low-cost control module communication, such as window, electric seat, headlight control, etc. Although it operates at a lower frequency (20kbps), ESD protection is still very important due to its single-wire communication structure and exposure at the connector end. Goals of LIN bus ESD protection:

- Resist electrostatic discharge (±8kV contact / ±15~25kV air)

- Do not affect LIN signal integrity (low frequency but maintain logic level)

- Meet automotive regulations (AEC-Q101, ISO 10605)

- Compatible with LIN transceivers (such as TJA1021, ATA663211)

We recommend the PESD1LIN automotive electrostatic suppressor product, which complies with the AEC-Q101 certification standard:

d.LED Lamp Beads

Automotive LED lamp beads are very sensitive to voltage changes during operation, especially when encountering voltage transients (such as load dumping, surges, lightning strikes, and reverse connection), which can easily cause damage. Therefore, a reliable overvoltage protection circuit must be designed for it to ensure long-term stable operation in harsh vehicle environments.

It is recommended to use the PLED06F series open circuit protector product, which adopts the SOD-123FL standard package. The product can provide a conversion electronic shunt when an open circuit failure occurs in a single LED in the LED light string. Therefore, even if an LED in the light string has failed, it can still ensure that the entire LED array continues to work, thereby providing more reliable lighting functions for lighting applications such as headlights, aircraft lighting, runway lighting, and roadside warning lights.

For more information on circuit protection solutions and applications related to automotive headlight products, please visit:https://en.semiware.com/applications/automotive-headlight/

About Semiware

Semiware has a comprehensive product lineup of circuit protection device products. The company leverages its technology in the semiconductor field and application background in end products to serve customers in the electronics, automotive and industrial markets. For more information, please visit semiware official website: https://en.semiware.com/

Comments (0)