⚡ Why Is It Important to Find Alternatives to the 30R500U?

In actual procurement and production, relying on a single supply chain can lead to the following risks:

- Excessively long or unstable delivery cycles

- Cost pressures associated with mass production

Therefore, engineers and procurement personnel typically evaluate dual-supply, triple-supply, and PPTC fuses compatible with the 30R series, without requiring significant design changes.

❓ Why Can Semiware’s SK30-500 Be an Alternative to the 30R500U?

For purchasing and engineering professionals, Semiware's SK30-500 offers the following advantages: 👇

- Stable and reliable performance

- Manufactured in our own factory, allowing us to offer customers highly competitive pricing.

- Compatible with common 30R series resettable fuses

- Reliable supply and technical support

- Reduces certification risks associated with alternative components

The following analysis details the substitutability of Semiware's SK30-500 in terms of performance parameters, size, and cost.👇

🔹 SK30-500 Key Electrical Parameters

| Parameter | Value |

| Part Number | SK30-500 |

| Package | SK30/30R |

| IHOLD (Max) (A) | 5.0 |

| ITRIP (Min) (A) | 10 |

| VMAX (V) | 30 |

| IMAX (A) | 40 |

| Time to Trip Current (A) | 25 |

| Time to Trip Time (s) | 14.5 |

| RMIN (Ω) | 0.01 |

| RMAX (Ω) | 0.05 |

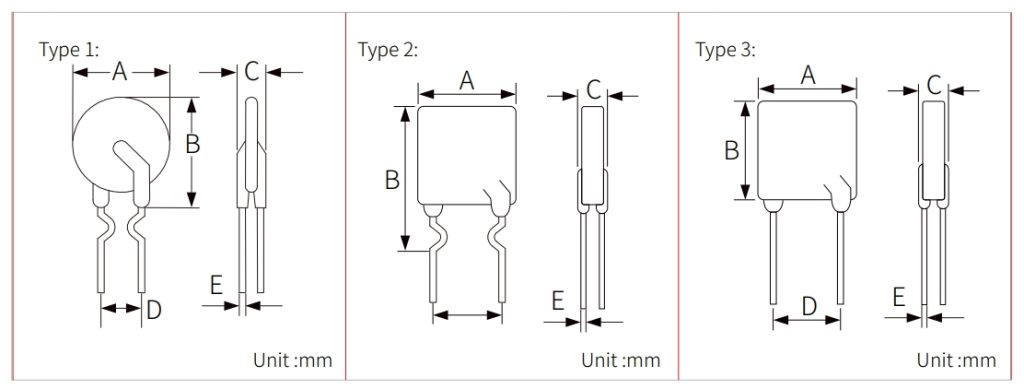

🔹 SK30-500 Outline Drawing

⭐ Multiple outline drawings are provided to illustrate different lead configurations and mounting options.

🔹 SK30-500 Typical Applications

SK30-500 is well suited for a wide range of low-voltage applications, including:

- USB devices and interfaces

- Mobile phone and tablet chargers

- Power adapters and switching power supplies

- Consumer and portable electronics

✔️ Cost Advantages and Flexible Ordering Options

1️⃣ In-House Manufacturing for Cost Efficiency

- Our own production facility allows for stable quality control while optimizing manufacturing costs.

- Ensures consistent supply without relying on external vendors.

2️⃣ Flexible Minimum Order Quantity (MOQ)

- We support adjustable MOQ options to meet both small and large production needs.

- Helps customers reduce inventory pressure and align orders with production schedules.

3️⃣ Volume-Based Pricing and Bulk Orders

- Large-quantity orders can benefit from negotiable pricing to optimize procurement budgets.

- Encourages long-term collaboration with cost advantages for high-volume production.

💡 Key Considerations When Choosing PPTC Resettable Fuse Replacement

When selecting an alternative to 30R500U, several factors should be carefully reviewed:

- Hold current and trip characteristics to ensure proper protection behavior

- Voltage rating compatibility for low-voltage circuits

- Radial-leaded package to match existing PCB layouts

- Time-to-trip performance for effective fault response

- Compliance requirements, such as RoHS and lead-free standards

- A suitable alternative should meet these requirements while maintaining stable and repeatable performance.

If you are designing compact circuits or upgrading overcurrent protection, Semiware provides a full range of SMD PTC fuses with stable performance and flexible supply. Detailed datasheets, cross-reference support, and technical guidance are available to help you select the right fuse for your application.

👉 Contact us to request product specifications, samples, or cross-reference recommendations.

❓ FAQs

1.What is PPTC Thermistors?

PPTC Thermistors is resettable overcurrent protection device that increases its resistance when excessive current flows and automatically resets after the fault is removed.

2.How does it compare to traditional fuses?

Traditional fuses are single-use and must be replaced after tripping, while PPTC fuses reset automatically and require no maintenance—ideal for consumer and portable electronics.

3.How does a PPTC fuse work?

During overcurrent, the polymer material heats up and expands, sharply increasing resistance to limit current. After cooling, it returns to its low-resistance state, restoring normal operation.

4.What is the difference between PPTC and PTC?

PPTC is a polymer-based PTC device designed specifically for resettable overcurrent protection, while standard PTC components are typically used for temperature sensing or inrush current limiting.

5.What is the difference between NTC and PTC?

NTC resistance decreases as temperature rises (used for sensing and inrush limiting), while PTC resistance increases with temperature (used for protection or heating functions).

Comments (0)