👀 Why TVS Selection Matters?

When you’re designing a circuit, a TVS diode acts like a lightning rod. It’s quiet most of the time, but the moment a surge hits, it jumps in to save your sensitive components.

The problem is, if you pick the wrong part, it might either fail to protect the circuit or interfere with normal operation.

🔧How to select the correct diode?

Here are six checkpoints that make selection easier. 👇

📌Working Voltage (VRWM): Don’t Make It Too Sensitive

A TVS should stay out of the way during normal operation. That means its standoff voltage has to be slightly higher than the circuit’s maximum working voltage—just enough to avoid false triggers. But don’t go too high either, or the clamping voltage will rise, and the downstream ICs may not survive the hit.

Rule of thumb: a little higher than your operating voltage, but not by much.

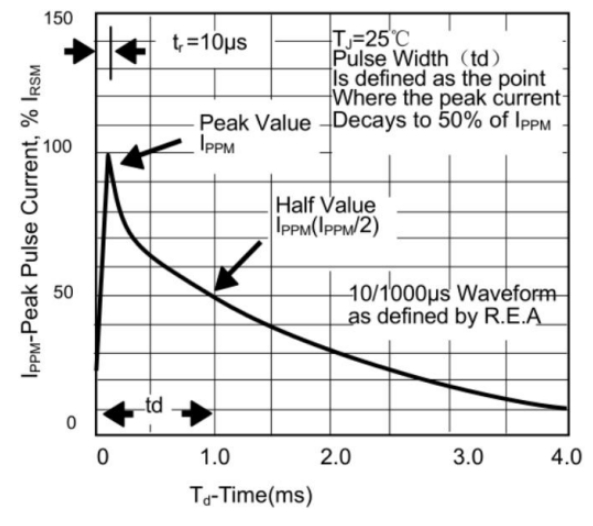

📌 Power Rating (PPPM): The Safety Margin

The rated peak power of a TVS needs to be larger than the maximum surge power your circuit might face. Quick math:

Power = Clamping Voltage (VC) × Peak Current (IPP)

For the same voltage, a larger IPP means the diode can handle more power. If your test waveform isn’t the standard 10/1000 μs but something like 8/20 μs, remember to recalculate.

Tip: always leave some headroom—once a surge exceeds the rating, the device won’t survive.

📌Clamping Voltage (VC): Keep It Below the Weak Spot

VC is the voltage the diode allows through during a surge. It must be lower than what your protected components can tolerate. Naturally, a higher breakdown voltage (VBR) or bigger pulse current (IPP) will push VC higher.

Simple rule: make sure VC < the maximum voltage your ICs or modules can handle.

📌Leakage Current (IR): Small but Not Ignorable

Ideally, you want IR to be as low as possible. Too much leakage increases power loss and can even skew precision signals. Low-voltage TVS parts (under 10 V) usually leak more, so if your circuit can handle it, aim for models rated 10 V or higher.

Note: if your system is very sensitive, stick with ultra-low-leakage parts.

📌Junction Capacitance: The Silent Speed Killer

TVS capacitance can mess with high-speed signals. A large junction capacitance means data lines like USB or HDMI may slow down or distort. Lower-voltage parts often have higher capacitance.

Bottom line: for high-speed or RF lines, choose low-capacitance TVS diodes.

📌Package Size: Bigger Isn’t Always Worse

The package directly affects how much energy a TVS can handle. Larger packages spread heat better and usually survive stronger surges. Of course, PCB space and mechanical limits also matter.

Tip: match the package size with the real surge threat and your layout space.

✅FAQs

- Q1: How to use a TVS diode in a circuit?

A: To use a TVS diode, place it across the voltage-sensitive points you want to protect—typically parallel to the load. Ensure the TVS diode’s working voltage matches your circuit voltage. When a transient voltage spike occurs, it clamps the excess voltage, protecting your components. Always check the peak pulse current rating to handle potential surges. - Q2: Where are TVS diodes commonly used?

A: TVS diodes are widely used in electronics where voltage spikes or ESD can occur, such as power supplies, automotive electronics, telecommunication equipment, consumer electronics, and industrial control systems. They are essential in safeguarding sensitive semiconductors and ICs. - Q3: How to connect TVS diode in circuit?

A: Connect a TVS diode in parallel with the component or circuit you want to protect. For unidirectional TVS diodes, the cathode goes to the positive voltage rail, and the anode to the ground. For bidirectional TVS diodes, connect across the voltage line without polarity concerns. Ensure the trace or wire can handle surge currents. - Q4: Is TVS diode a zener?

A: While TVS diodes and Zener diodes share voltage-clamping characteristics, they are not the same. TVS diodes are designed for fast transient suppression with high peak current capacity, while Zener diodes are typically used for voltage regulation under steady-state conditions. - Q5: What causes TVS diodes to fail?

A: TVS diodes fail mainly due to exceeding their maximum peak pulse current, prolonged overvoltage, or repeated transients beyond rated limits. Other causes include poor soldering, reverse polarity connection (for unidirectional types), or thermal stress in high-power circuits. Proper selection and placement are critical for long-term reliability.

🌏Looking for reliable TVS diodes? Explore our full product line and buy TVS diodes from a trusted supplier. We offer certified components, long-term availability, and flexible bulk ordering options to keep your circuits protected.

Comments (0)